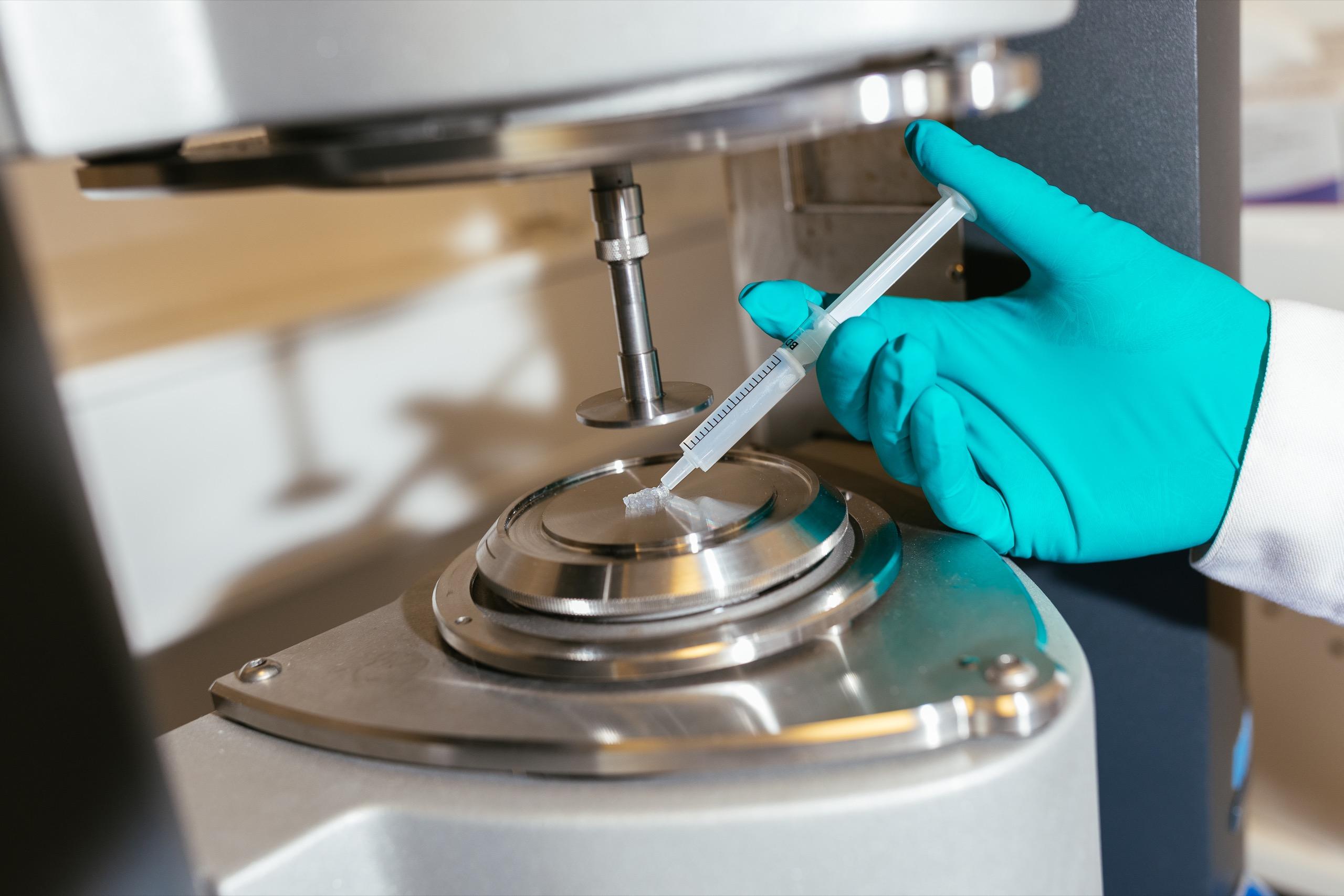

Custom Synthesis for Durable and Degradable Hydrogels

Whether for drug delivery or use as part of a medical device, durable

and degradable hydrogels are used in a wide range of applications. These applications require the

highest quality hydrogels to ensure the safety and effectiveness of the device or pharmaceutical.

To achieve high-quality hydrogels, we offer full-scale polymer development, from initial synthesis to

analysis. At Chempilots we've worked extensively with hydrogel materials, and have over 60 years of

experience working with polymers. With a dedication to quality and accessibility, we’re here to

support you throughout the development process.

Medical Devices

Durable hydrogel polymers don’t break down over time, making them a great solution for contact

lenses and other durable medical devices. Degradable hydrogels that dissolve over time work well

in applications such as wound dressings.

Durable Bulking Agents

Durable hydrogel polymers are often found inside injectable bulking agents, such as the ones used

in urology for endoprosthesis. Hydrogels can also be used to develop soft tissue scaffolds for

the same application.

Pharmaceuticals

Applications such as controlled drug release dermal patches, medicinal creams, ointments and oral dosage

forms can benefit from degradable hydrogels. Hydrogels work well for extended and controlled

drug delivery requirements.

Why Chempilots?

Chempilots is here to help you develop hydrogel polymers to fit your specific applications. Our

full-scale development services include everything from custom polymer synthesis to manufacturing. Plus,

you’ll experience all the benefits

of working with Chempilots:

- 60+ years of experience: Chempilots has been developing durable and degradable

hydrogels for

decades. We have the experience necessary to ensure the highest quality polymers for pharmaceuticals

and medical devices.

- Customized development services: Our full-scale polymer development services are

scalable and

customizable to fit your needs. Whether you require contract manufacturing or polymer analysis, we

can deliver.

- ISO 9001 certification: When it comes to the pharmaceutical and medical device

industries, safety is

of utmost importance. We’re dedicated to providing the safest polymers for your application.

That’s why our quality management system is ISO 9001 certified.